Anything you do in Epicor® can be automated through Service Connect®. This ability allows you to merge your Epicor® system with an external system (or business process). You can generate records in Epicor® on a massive scale while still being governed by the Epicor® system’s business intelligence. Below are some examples to show you how Service Connect® works and what it can do for your business.

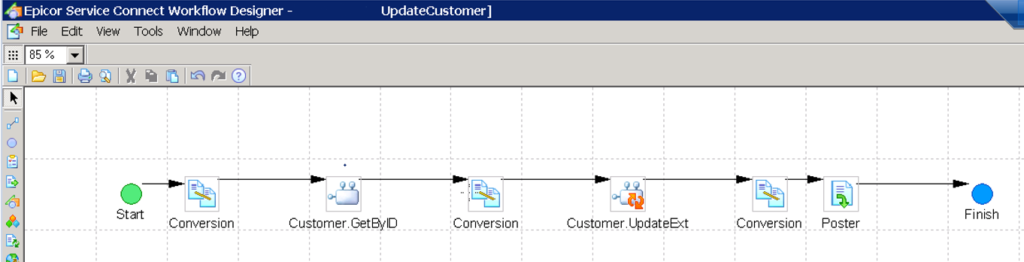

PracticalTek: Update Customer Records

Using an Excel File and Verify Them

What we did: We created an Epicor® Service Connect® solution that not only automated data entry, but it generated a .CSV file that was then sent to the customer to verify the accuracy of those changes.

Why? This customer’s sales team would use Excel while traveling. The team would take many notes, and frequently those notes consisted of changes to customer information. After the team would return, they would manually update their customer information using these notes, and sometimes they were inaccurate.

Q. How is this helpful for you?

A. This Service Connect® solution exemplifies how it’s possible to increase your productivity by eliminating unnecessary data entry. Not only did Service Connect® eliminate the need for data entry, but it also increased the integrity of the data by verifying the changes with the customer. Service Connect® can be used in many ways; not only can it create files but it can also automatically email them. It’s also important to note that Service Connect® can stop the processing of data until verification is received from an individual, a group of individuals, or by another automated Service Connect® process.

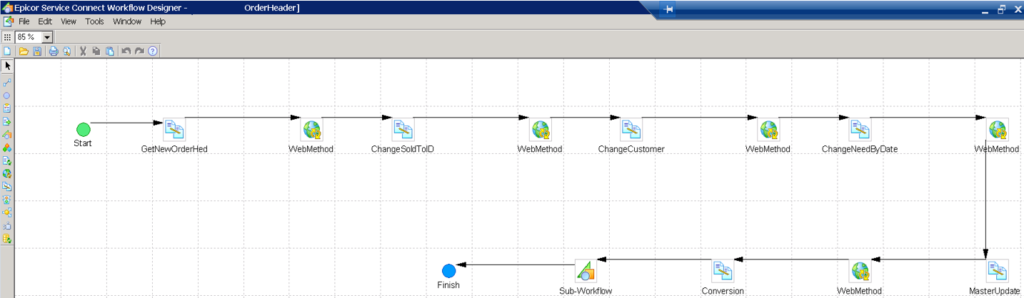

PracticalTek: Create Order Header and Order Lines

from a .CSV File

What we did: Created a Service Connect® solution that used a .CSV file to create orders and their lines.

Why? This customer purchased a smaller company that used their own Legacy system. They needed the orders from this company to be entered into Epicor® and doing this manually was not feasible.

Q. How is this helpful for you?

A. This is a good example of merging Epicor® with an external system. Using the power of xml, Service Connect® can integrate any system with Epicor®.

Using the data from the .CSV file, this workflow creates the Order Header information and saves it to Epicor®. This is where we “call” the workflow below that creates the Order Lines. Service Connect® adheres to all of the business logic in Epicor®.

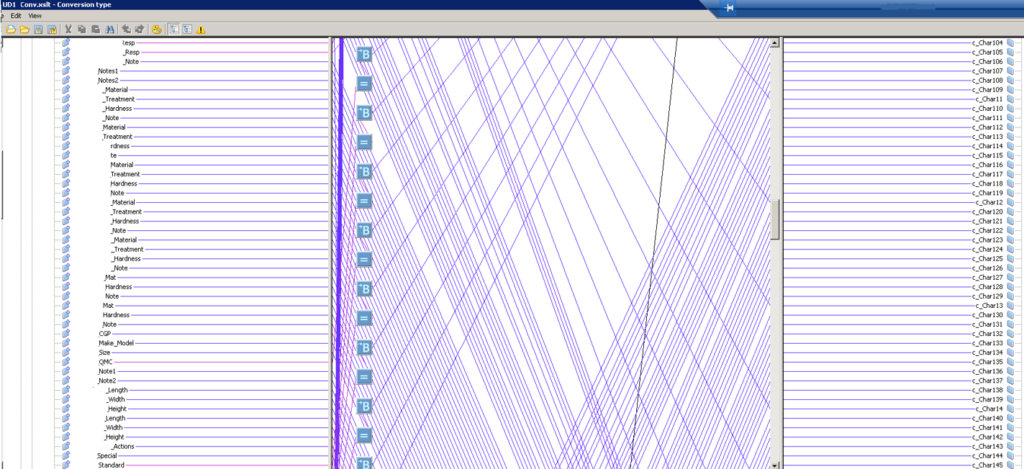

Epicor® Service Connect Workflow Designer

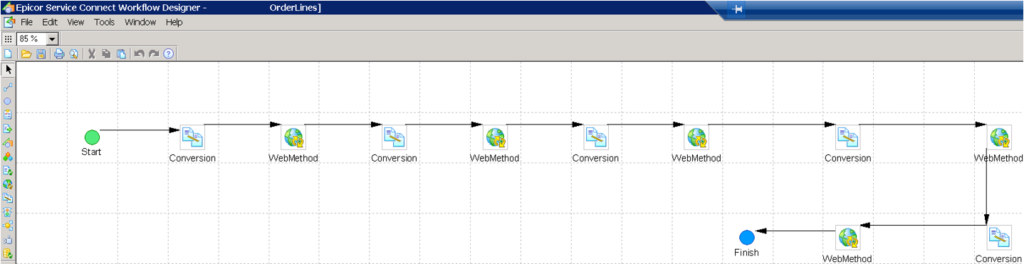

This workflow cycles through each line that is to be added to the Epicor® database checking each to ensure they adhere to the business logic of Epicor®

PracticalTek: Auto-Ship and Invoice Sales Orders

Using a .CSV File

What we did: Our customer was recently joined with a parent company that had their own Warehouse Management System (WMS). Once a product was considered received by the WMS system a .CSV file containing order information was sent to them. We used the .CSV file’s order information to automatically create customer shipment records, flag them as “Ready to Invoice” and finally we invoiced the order as well. All of this was done automatically by our Service Connect® solution.

Q. How is this helpful for you?

A. This example shows how you can automate complex business processes such as creating an invoice or shipment. If you are merging with another company that uses a standardized way of processing data, a Service Connect® solution can bridge that gap. Best of all, once your Service Connect® solution is finalized the process is fully automated, letting you get back to what you do best.

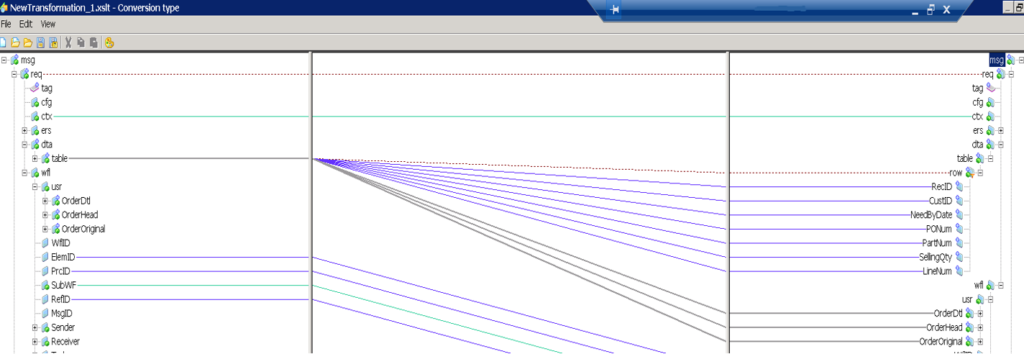

This conversion is just one of over 20 needed to build this Service Connect® solution. It is simply validating the order information coming from the .CSV file.

PracticalTek: Merge an Excel Sheet

with an Epicor® User Defined Table

What we did: This customer had a very impressive Excel sheet. This sheet was so complex that it was essentially a stand-alone program in itself. They used this sheet as an aide to their business process, and it was essential that they continue to use it. They also wanted all of the data from this sheet to be available in Epicor®. They built a process in their Excel sheet that would export an .xml file. After exporting the file, they needed the information to be inserted into the Epicor® database immediately. Service Connect® can do just that; we created a solution that automatically updated a UDTable using the values taken from the Excel Sheet.

Q. How is this helpful for you?

A. Many of our customers use Excel often and for good reason. These same customers wish there was an easy way to get the Excel data into the Epicor® system. Well, Service Connect® was practically built for this purpose; it can update any table with Epicor®. Don’t let your business waste time manually entering in data that comes from an Excel sheet. Service Connect® can do it for you in the blink of an eye.

The formatting for this conversion was rather complex. Here we see a group of fields being converted into Boolean values (true/false).